AMERICAN PLACE CASINO

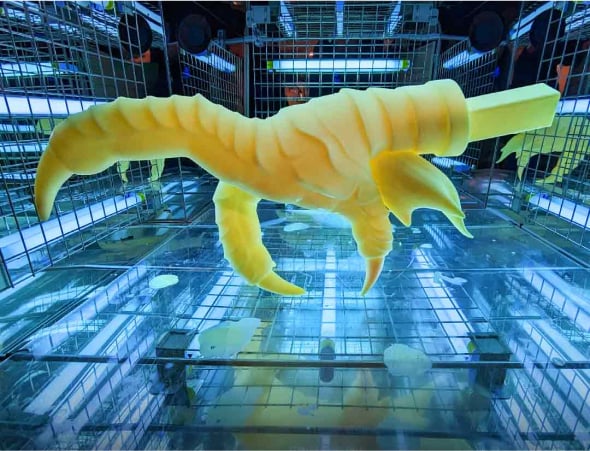

Breathing Life into 3D Printed Dragons

Destinations by Design, an event production and destination management company, came to Bridgewater seeking two larger-than-life, ultra-detailed 3D dragons for an Asian-fusion-themed casino restaurant in Illinois.

The Challenge

Strategy

In order to nail down final color, shape, and texture decisions, our team 3D printed two precisely detailed one-inch scale maquettes, to help the client visualize the end product and sign off on each stage with confidence.

Design

Working from a handful of images and a block model for inspiration, we went to work creating mood boards for texture, color, and shape. Then, we used 3D visualization software to predetermine location, size, and exact positioning—to ensure a smooth installation and a seamless guest experience.

Production

To build each 2600 lb sculpture, steel skeletons were engineered and fabricated using CNC fiber laser cutting machines to support each dragon. Cable chases for electrical wires illuminate the dragons’ LED backlit eyes, which were 3D printed from clear resin.

By simultaneously running 10 industrial SLA 3D printers, the dragons were printed in weeks versus what could have easily taken months.

Have an experience in mind?

Here are 3 easy ways to get started...Explore Examples

View our project portfolio for ideas, inspiration, and helpful information.

Ballpark Your Budget

Use our Estimation Agent to see how much your next project might cost.