MUSEUM OF SCIENCE & INDUSTRY: FRICTION

Friction + Speed: Using Gravity to Teach Science

When the Museum of Science & Industry, Chicago (MSI) came to us seeking a new interactive exhibit about friction, we were intrigued by the challenge of making the concept fun and enticing for visitors of all ages. Plus, the new concept needed to fit seamlessly within an existing gallery.

The Challenge

Strategy

Because museum exhibits are subject to heavy use and frequent maintenance issues, our principal concern was how to convey the science accurately with a repeatable, engaging experiment that allowed for guest interaction without sacrificing the longevity of the device. In other words – it needed to work all day every day. An ingenious exhibit is worthless to guests (and the museum) if it is out of service. Durability was key.

Design

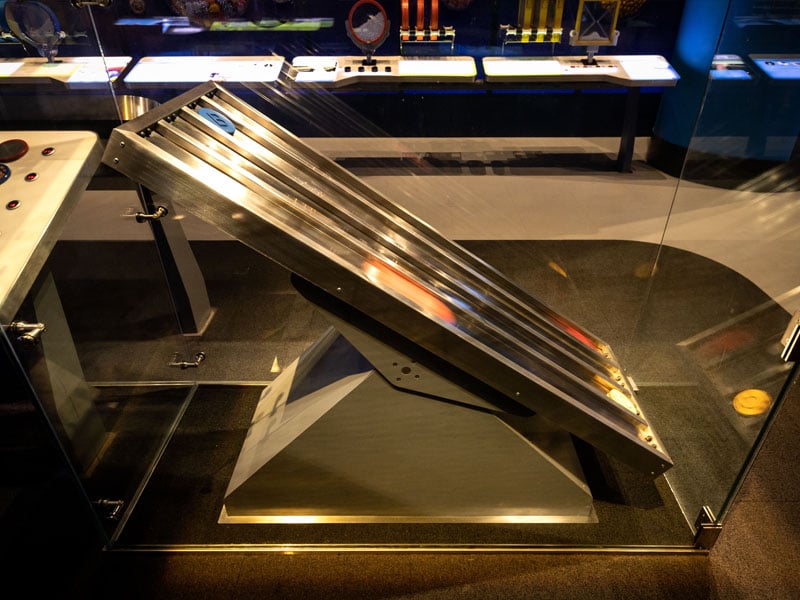

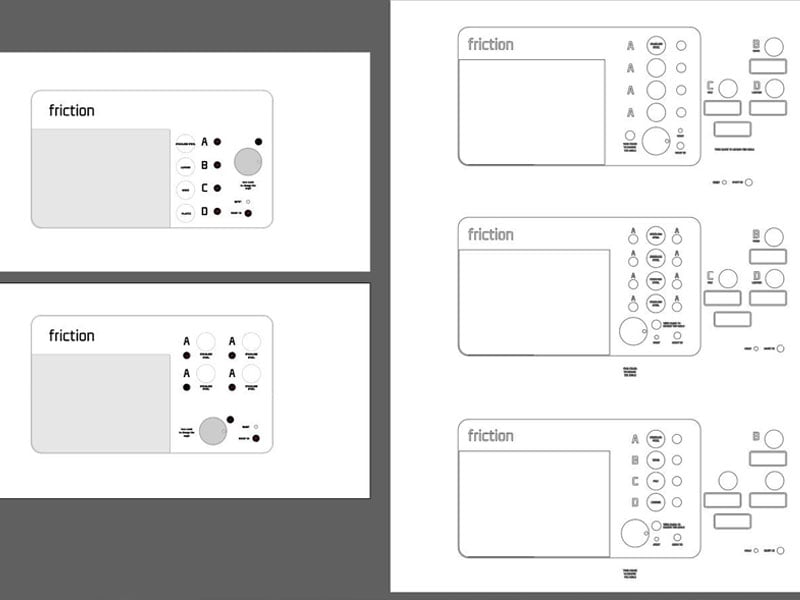

To make friction visually interesting, our team developed the concept of a materials race using gravity. To demonstrate this we designed a tilting table, much like a see-saw, that visitors can manipulate to run repeatable, real-time experiments to see how pucks made of different materials perform side-by-side in a race. Many materials were prototyped and tested to determine which would best convey the principles of friction. After multiple prototypes were built to test the mechanism, reset, and UI, the machine was ready for fabrication.

Production

Bridgewater's signature digital fabrication process flowed seamlessly into production, ensuring precision throughout. Employing a combination of CNC and 3D printing, the components of the tilting table were fabricated from a variety of materials including stainless steel and translucent Corian™. Additionally, all electrical integration and controller programming was performed in-house.

The end result? An interactive exhibit accurately portraying the principles of friction while seamlessly integrating into an existing gallery aesthetic and precise footprint. A win for MSI and a delight for guests of all ages.

Have an experience in mind?

Here are 3 easy ways to get started...Explore Examples

View our project portfolio for ideas, inspiration, and helpful information.

Ballpark Your Budget

Use our Estimation Agent to see how much your next project might cost.