Computer-aided additive manufacturing processes have revolutionized industries such as aerospace and medicine. Commonly referred to as 3D printing, this technology enables designers to send a set of detailed instructions to a machine which then fabricates their design.

Initially valued as a means of rapid prototyping, today 3D technology is used to develop everything from medical devices to sculptures, custom machine parts, and more out of a range of 3D printing materials.

As 3D printing technology advances, so do its applications and the materials used for 3D printing. This article explores some of those materials and how they empower designers, artists and manufacturers to innovate and build great things.

Modern materials expand the possibilities of 3D printing

Many 3D printers use plastic resins to create prototypes, forms and the foundations for finished pieces. But plastic isn’t the only material that has made its way into the 3D printer universe. With an expanded collection of materials from which to choose, manufacturers, artists and other builders can use 3D printers to create objects suitable for applications ranging from industrial to sculptural—and even fine dining.

Some 3D printers accommodate polymer resins that are combined with other materials such as ceramics, enabling these printers to produce finished pieces with a stone-like appearance. They make other 3D printers to use specialty materials such as metals or glass.

Check our list of some of the most common and innovative 3D printing materials and the industries that use them.

3D printing materials used by designers, manufacturers, sculptors and artists

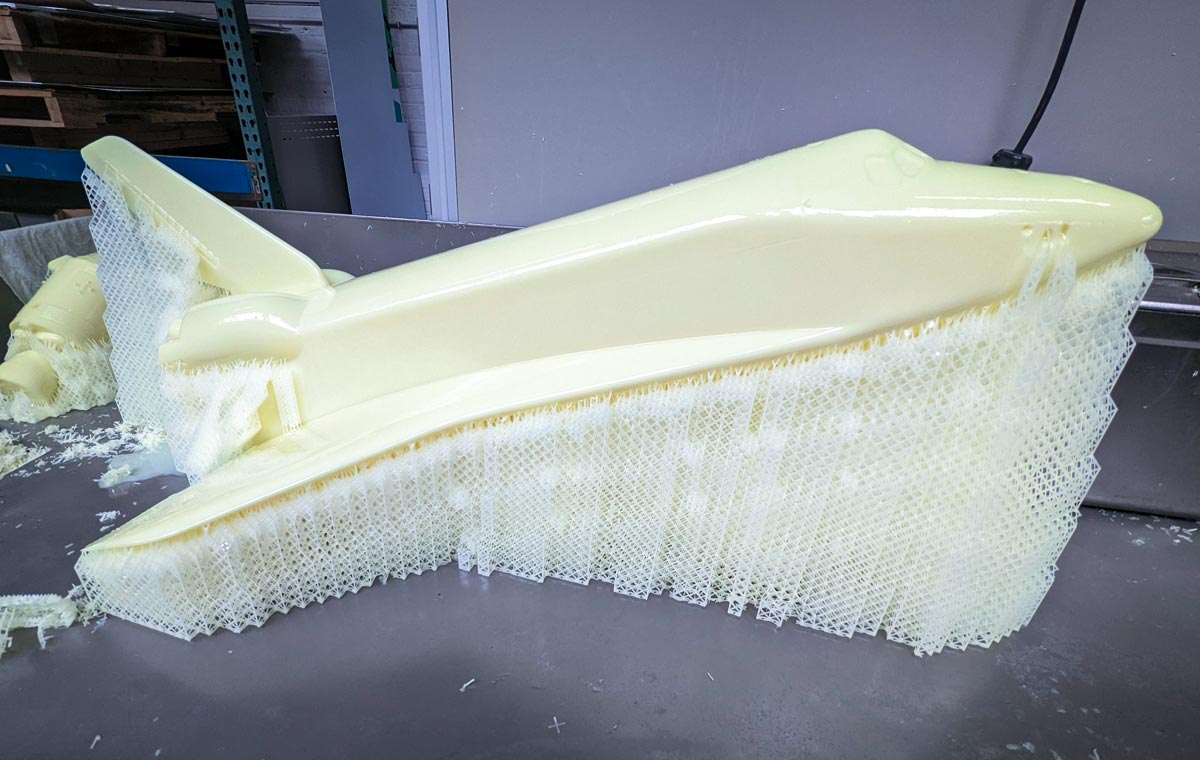

From creating one-of-a-kind film and stage props to building propellers for luxury water crafts, these 3D printing materials get the job done:

- Polymers and plastics

Polymers and plastics are versatile and accessible, making them a popular choice for a range of applications. 3D printing resins like the type used in Stereolithography (SLA) 3D printers can produce objects that are flexible or rigid. Acrylic items can be crafted using clear 3D printing resins.

Polymers combined with additional materials are used to build objects that can withstand high-temperatures or exposure to the elements. You can even print using elastic resins that create objects that will rebound to their original shape when stretched.

Finished items printed in plastic serve several industries. The material is also an economical choice for creating models and prototypes, or positive or negative molds for customized fabrications.

The popcorn pieces that make up this climbing wall were cast using a 3D printed plastic negative mold. - Metals

Metal 3D printing materials open the door to creating objects including jewelry or heavy machine parts. While most desktop-sized printers can only accommodate some metal composites, large-scale 3D printers use real metals to build in 3D. For example, GH Induction used electron beam melting (EBM) technology to print a pure copper coil. - Concrete

Speaking of architecture, large-scale 3D printers can now create sculptures, architectural elements or entire buildings using concrete. Building on-site with 3D technologies such as layered construction or robotic additive fabrication enables architects and builders to create precise, customized structures.

There are a few different kinds of concrete used for 3D printing. Some materials that result in a concrete-like finish are actually modified to perform better when sculpted using 3D printing technology. Traditional concrete can clog 3D printing nozzles and the concrete layers don’t always adhere well to one another.

However, in 2022, CEMEX announced that it had constructed a 2,100 square foot home using a layering method and “real concrete.” This is a significant advance for 3D construction printing because it lowers the materials costs for building houses, schools and other structures. - Soil

Can you print using soil? Yes. Clay is among the oldest building materials known to man. With concrete like properties, soil is moldable and flexible prior to drying or curing. This makes the material a suitable candidate for 3D printing. In the performative lab space To Grow a Building, designers use a robotic arm to 3D print structures made from soil and seeds. - Human cells

3D printing materials used for the medical field include ceramic resins, often made by infusing a plastic polymer with silica that hardens to a ceramic-like strength when cured. 3D printing enables superior color-matching and fit for dental prostheses. Modern 3D printed casts are strong, waterproof and custom-fitted (no more plastic bags over your arm to take a shower). - Chocolate

3D printing materials are making waves in industries far removed from manufacturing and medicine, too. In the food industry, 3D printers allow pastry chefs and chocolatiers to create fascinating, sculptural treats using chocolate!

Expect more innovation as 3D printing technology embraces new materials and applications

Manufacturers, builders, and other creators haven’t exhausted the possibilities of 3D printing yet. Far from it. In fact, the bar is being raised every day as 3D printing materials and capabilities evolve.

As a full-service experience design, production, and strategy company, we’re on the front lines—using liquid resin 3D printing to create custom elements for applications ranging from architecture to exhibits, brand activations, art installations, motorsports, and beyond. A dedicated work cell with 9 machines and 400 cubic feet of 3D printing capacity is just one part of a comprehensive suite of resources and expertise that makes it all possible.

Have a one-of-a-kind project in mind? Learn how a single partner can help you navigate the options, choose the right technology, and enjoy a seamless process from concept to completion. Schedule your introduction to Bridgewater Studio today.

.png)

.png)

.png)